Error de formato de correo electrónico

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

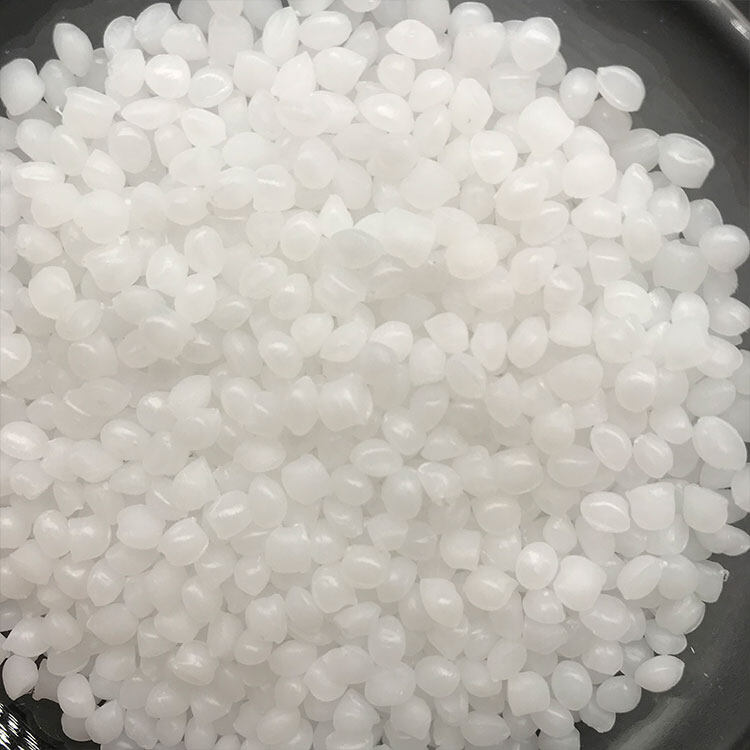

PP T20 HN_PP+EPDM-TD 20

Talcum Filled: 20%

SGS Verified

(Custom materials available according to your Technical Data Sheet)

- Detalle del producto

-

Download

Customizable Materials Available:

- Color (Customization of plastic pellet color according to your requirements.)

- Flame retardant grade (Let us know which flame retardant level you need: 0.8mm-3.0mm HB, V0, V1, V2, 5VA, 5VB)

- Glass fiber reinforcement material (10%-50% availability)

- Carbon fiber reinforcement material (10%-50% availability)

- UV resistance property (Tell us the application scenarios or UV resistance level of the materials.)

- Other materials can also be customized (Just need to provide your Technical Data Sheet.)

Technical Data Sheet of PP T20 HN_PP+EPDM-TD 20

PP T20 plastic resin pellets is a type of polypropylene (PP) material that incorporates the addition of 20% talc as a filler. This combination results in improved properties and performance characteristics. Talc acts as a reinforcing agent, enhancing the material's stiffness, dimensional stability, and resistance to impact. PP T20 is known for its excellent heat resistance, chemical resistance, and electrical insulation properties. It finds applications in various industries, including automotive, electrical appliances, packaging, and consumer goods.

The Feature of Polypropylene Compound PP T20 Granules

-

Enhanced Stiffness and Dimensional Stability:

Polypropylene PP T20 granules, being 20% talc filled, exhibit increased stiffness and dimensional stability compared to unfilled polypropylene. This makes them suitable for applications that require rigidity and resistance to deformation. -

Improved Heat Resistance:

Polypropylene PP T20 granules with talc filler offer enhanced heat resistance. They can withstand higher temperatures without significant degradation, making them suitable for applications involving exposure to heat or hot environments. -

Increased Impact Strength:

The addition of talc as a filler in PP T20 granules improves their impact strength. They can better withstand impacts and shocks, reducing the risk of damage or cracking. This feature is valuable in applications that require impact resistance. -

Reduced Shrinkage:

Polypropylene PP T20 granules filled with talc tend to exhibit reduced shrinkage during the molding process. This can result in improved dimensional accuracy and reduced warping in the final product.

The Advantage of Polypropylene PP Granules with Talc Filled

-

Enhanced Mechanical Strength: Talc acts as a reinforcing filler in PP, improving its stiffness, tensile strength, and impact resistance. This can result in stronger and more durable products.

-

Improved Heat Resistance: Talc has excellent thermal stability, which helps to enhance the heat resistance of the PP material. This makes it suitable for applications that involve exposure to high temperatures.

-

Increased Dimensional Stability: Talc-filled PP granules exhibit reduced shrinkage during cooling, leading to improved dimensional stability. This is beneficial for achieving precise molding and maintaining the desired shape of the final product.

-

Reduced Warpage: Talc can contribute to minimizing warpage in PP parts by controlling the cooling rate and reducing internal stresses. This results in enhanced aesthetics and better overall performance of the product.

-

Enhanced Surface Finish: Talc-filled PP granules offer improved surface smoothness and reduced surface roughness. This can have a positive impact on the appearance and feel of the final product.

PPT20 combines the advantages of polypropylene (PP) with the added strength and stiffness provided by 20% talc filler, resulting in an exceptional material for automotive applications.

One of the key benefits of PPT20 is its excellent mechanical properties. The addition of talc enhances the material's stiffness, allowing it to withstand the demands of automotive interior environments with ease. It provides enhanced dimensional stability, reducing the risk of warping or distortion over time.

Moreover, PPT20 offers outstanding heat resistance, making it highly durable in extreme temperature conditions. It can resist high temperatures without compromising its structural integrity, ensuring reliable performance even in challenging environments.

Another advantage of PPT20 is its aesthetic appeal. The talc filler gives the material a smooth and matte finish, creating a refined and luxurious look for automotive interior pillars. Its versatility allows for various customization options in terms of color and texture, enabling car manufacturers to achieve stunning and visually appealing designs.

With its exceptional combination of strength, heat resistance, and aesthetic appeal, PPT20 is the perfect material for manufacturing automotive interior pillars that prioritize durability, performance, and style.

As manufacturers of polypropylene resin, we welcome your inquiries.

With our extensive expertise in the pp compound market, we proudly stand as one of the top polypropylene pellet suppliers. We offer a vast range of PP options to cater to your specific requirements.

If you are polypropylene resin distributors or users, we ensure prompt delivery and exceptional customer service. Our goal is to supply you with top-grade products that elevate your manufacturing processes.

Rest assured, our polypropylene resin is of outstanding quality and available for sale. We understand the significance of employing excellent materials, this is why we are reputable polypropylene resin suppliers.

If you have any inquiries about our products or would like to discuss pricing, please contact us, we could provide competitive polypropylene resin price.

PP EPDM material is a type of thermoplastic elastomer compound that combines polypropylene (PP) with ethylene propylene diene monomer (EPDM) rubber. EPDM is a synthetic rubber known for its excellent weather resistance, heat resistance, and durability.

By blending PP with EPDM rubber, the resulting material exhibits properties of both plastics and rubber. PP EPDM materials are often used in automotive applications, construction seals, weatherstripping, gaskets, and other applications where a combination of flexibility, weather resistance, and mechanical properties are required.

PP EPDM compounds offer benefits such as good weathering resistance, enhanced impact strength, flexibility over a wide temperature range, and improved aging resistance compared to standard polypropylene.

Is EPDM rubber or plastic?

Ethylene Propylene Diene Monomer (EPDM) is a type of synthetic rubber, not a plastic. EPDM rubber is widely used in various applications due to its excellent weather resistance, heat resistance, electrical insulation properties, and chemical resistance.

EPDM rubber is known for its durability, flexibility, and resilience over a wide range of temperatures, making it a popular choice for sealing materials, gaskets, roofing membranes, automotive parts, hoses, and other applications where a reliable elastomeric material is needed.

While EPDM shares some properties with plastics, it is fundamentally a type of rubber due to its elastomeric nature and ability to deform under stress and return to its original shape when the stress is removed.

EPDM stands for Ethylene Propylene Diene Monomer, which is a type of synthetic rubber material. EPDM is known for its excellent resistance to heat, ozone, weather, and aging, making it suitable for a wide range of applications in various industries.

EPDM rubber is widely used in automotive parts, weather seals, roofing membranes, electrical insulation, hoses, gaskets, washers, and other applications where resistance to environmental elements and durability are crucial.

It is a versatile material with properties that include good weatherability, ozone resistance, thermal resistance, electrical insulation, and excellent water resistance. EPDM is often used in outdoor applications due to its ability to withstand exposure to sunlight, heat, and other weather conditions without deteriorating quickly.

Download

-

拓扑新材料 PP HN_PP+EPDM-TD 20.pdf

Download 拓扑新材料 PP HN_PP+EPDM-TD 20.pdf